With COP26 in Glasgow almost upon us, news about initiatives to reduce the environmental impact of human activity on the earth is never far from the headlines. And while there is much we can do as individuals to mitigate our own carbon footprints, the challenge facing industry is not insignificant.

One surprising area that could have a key role to play in industry’s efforts is improvements in digital connectivity.

A recent report from Mobile UK highlighted that 5G enabled technology could help the combined G7 manufacturing sectors reduce their total carbon emissions by 1%.

This may not sound like a huge difference from the outside but that figure equates to some 2.6MtCO2e by 2025. So how can this be achieved?

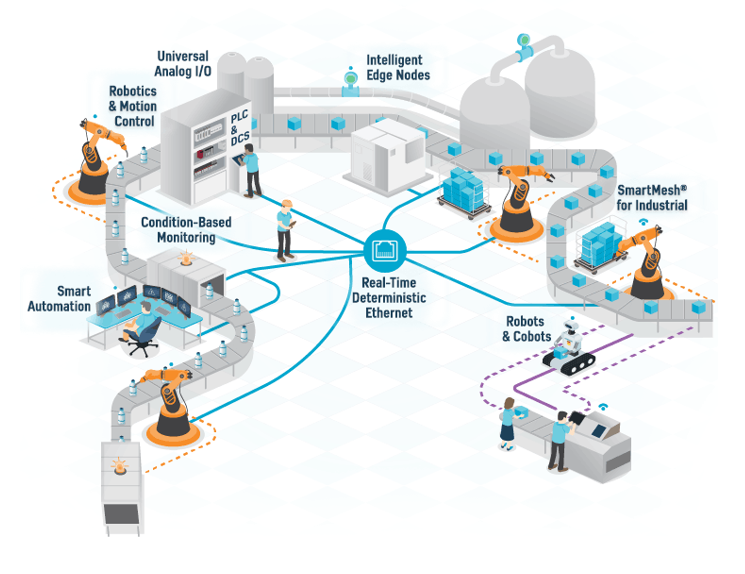

The key is that 5G is set to enable wide scale adoption of more intelligent, smarter manufacturing processes. Interconnectivity enables a move away from traditional ‘linear’ manufacturing processes to more agile, dynamic operations designed to maximise efficiencies.

For example, machinery can be monitored to identify demand trends, allowing for smarter use of resources and greater efficiency. This has has a knock-on beneficial impact on energy use, pollution and waste. As demonstrated by AE Aerospace, automated inspection processes enabled by 5G technology can also reduce waste, identifying areas for concern at an earlier stage to subsequently increase precision and reduce faults.

Using existing infrastructure, increased data transmission would require increased energy to transmit that data, but 5G represents a step change in terms of the amount of data that can be transmitted over a certain timeframe, effectively improving the efficiency of that data transfer. In short, 5G enables IOT technologies to use less power to transmit more data.

To find out more about how 5G could help your business improve operational performance while reducing its environmental impact, contact us, or take a look at some of our use cases here.