nexGworx has played a key role in the successful installation of a pioneering private 5G network at the Manufacturing Technology Centre (MTC) in Coventry.

As a result of the Government’s 5G Testbeds and Trials programme, nexGworx – supported by its technology partners BT and Nokia – collaborated with West Midlands 5G (WM5G) to install the standalone 5G private network. This will give SMEs, corporate members, neighbouring universities, and the wider industry the opportunity to explore private 5G and on-premises multi-edge computing, driving forward innovation in the region beyond the duration of the programme.

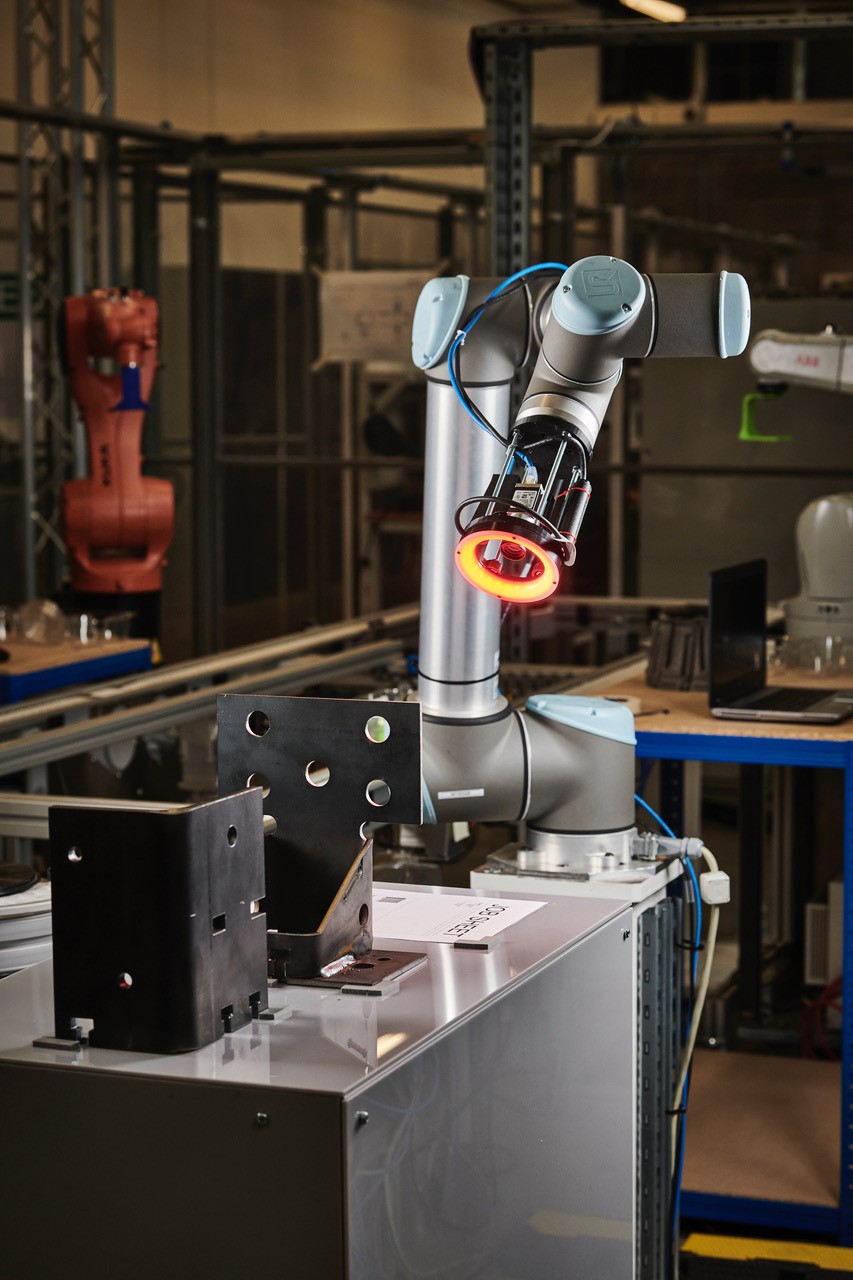

The MTC has just launched its first 5G-enabled demonstrator system to trial the technology, featuring 5G-connected robotics, computer vision and edge computing.

The trial showcased an automated inspection process to prove how intelligent automation and advanced connectivity could enable manufacturing sites to maximise productivity and utilisation of inspection technology, whilst reducing footprint and product waste.

Ste Ashton, of nexGworx, explained: “In many production environments, components of varied sizes and shapes are produced and need to be measured and checked to meet design tolerances. Traditional in-person inspections can be time consuming, are prone to human error and are not automatically recorded.

“Communicating via the private standalone 5G network, automated and fast visual inspections can check that each component meets specification using high-definition cameras, before autonomously delivering parts to the next stage in the process.”

By using mobile industrial robots for transporting parts and supporting the automation of visual inspection processes, equipment becomes more flexible to increase productivity and utilisation, while meeting quality assurance needs at any stage of the process.

Using 5G technologies, manufacturers can find smart solutions to tackle challenges and replicate best practice, boosting overall sector performance and supporting an environmentally sustainable economic growth.

Robert Franks, Managing Director at WM5G, said: “Manufacturing is at the heart of the economy in the West Midlands, and at WM5G we are working collaboratively with our partners to ensure that public and private sector organisations can remain competitive in the global marketplace and develop cutting edge technologies to advance their capabilities.

“We are so pleased to have delivered a successful trial in partnership with nexGworx and BT at the MTC, driving forward the transformation of manufacturing productivity for the region. The learnings and outcomes from our demonstration will now be used and applied across the sector to ensure best practice is carried forward, and to accelerate the adoption of 5G technology more widely.”

Alejandra Matamoros, Technology Manager in the MTC’s Digital Engineering Group, said: “Conventional production environments often require in-person inspection of components, which not only use valuable work hours but can result in human error. Automating this process enables skilled staff to focus on more valuable tasks, seamlessly generate records of part quality, and allows to efficiently increase quality checks.

“Continued testing and the sharing of learnings and best practice are the key to future innovation and development. Our connected facility at the MTC will allow manufacturers of all sizes, research, and technology suppliers to explore the benefits of 5G in manufacturing.

“Through our enduring collaboration with nexGworx and BT we are now planning to build on the initial capability we’ve created here at the MTC, pushing the boundaries of what can be achieved with the help of 5G technology.”